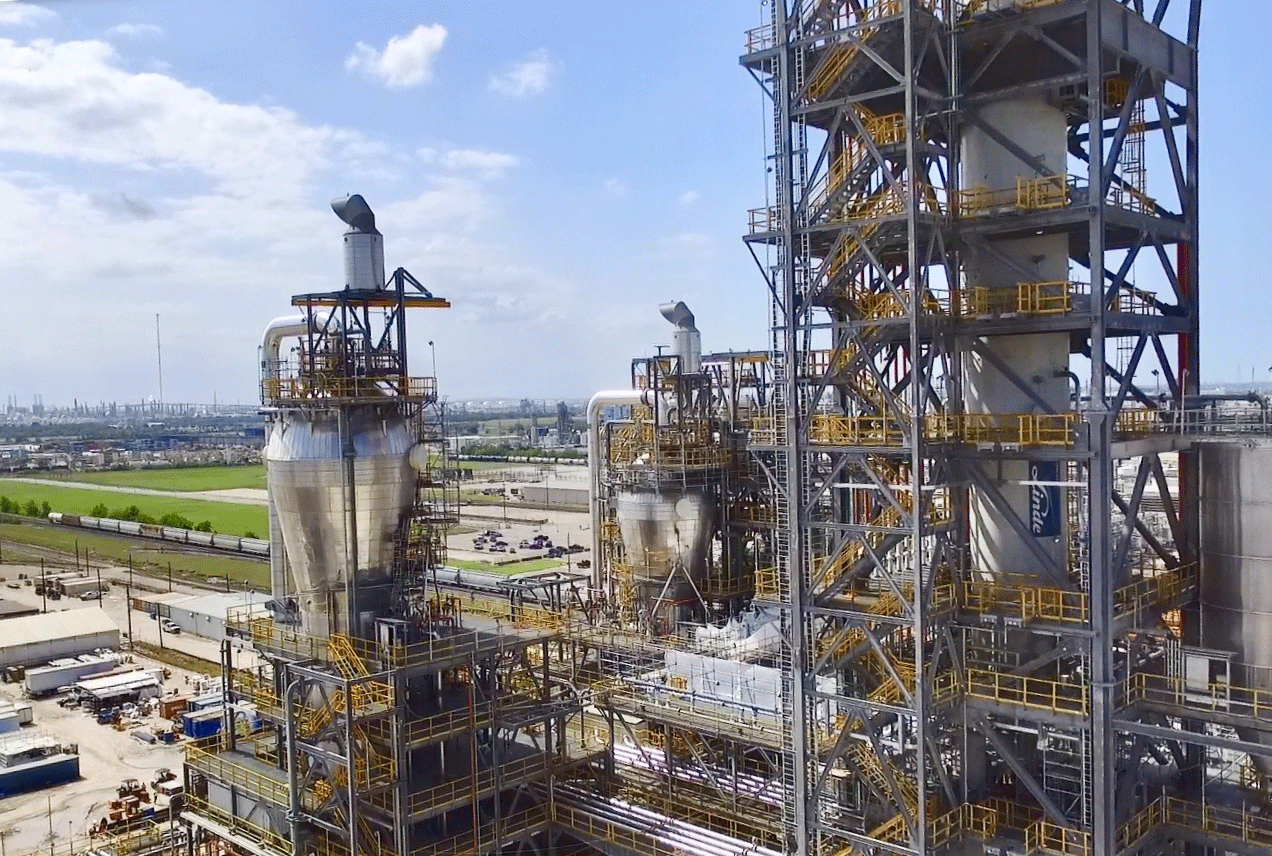

Braskem Celebrates One Year Anniversary of Commercial Production at its Newest World Class Polypropylene Production Line in La Porte, Texas

Philadelphia, Pa. - September 10, 2021 - Braskem (B3: BRKM3, BRKM5 and BRKM6; NYSE: BAK; LATIBEX: XBRK) ("Company"), the largest polyolefins producer in the Americas, as well as a market leader and pioneer producer of biopolymers on an industrial scale, announces the celebration of the successful one-year anniversary of commercial production at its newest world class polypropylene (PP) production line in La Porte, Texas.

Mark Nikolich, Braskem America CEO, commented, "Braskem's first full year of commercial operations at our newest world class polypropylene line in La Porte, Texas, exceeded our expectations for quality and performance at a time in the industry when our clients needed us most. Our decision to invest in North America's largest polypropylene production facility reflects our commitment to our leadership position in the U.S. market and more importantly, enhancing our ability to meet the current and future needs of our clients. The enhanced production capabilities from this new facility proved critically important as the larger industry supply was negatively impacted by Winter Storm Uri."

Initial commercial production was launched September 10, 2020, at Braskem's newest PP production line with a nameplate production capacity of 450 kilotons (kt) or 1 billion pounds per year. In the first full year of commercial operation, the plant produced over 800 million pounds (365 kt) despite the challenges faced from Winter Storm Uri and it consistently ran at or above its nameplate capacity through the year.

Braskem America's newest PP production line was designed with the capability to produce the entire polypropylene portfolio including a broad range of products such as homopolymer, impact copolymer and random copolymers. During the first year of operations, the plant successfully produced multiple unique grades of homopolymer, impact copolymer, and random copolymers with these capabilities demonstrated across dual production reactors. Braskem clients leveraged these commercial PP grades to serve a wide range of applications, including: housewares, automotive compounding, medical protective equipment (PPE), food and beverage applications, packaging, films, industrial piping, carpeting, and much more.

Alexandre Elias, Vice President U.S. Olefins & Polyolefins, Braskem America said, "The launch of production at our newest manufacturing line in La Porte has significantly improved the capacity as well as efficiency of our entire U.S. polypropylene production portfolio, with our new line producing some of the highest volume commercial grades at significant scale. This combined with design innovations as well as advances in production sustainability have enabled us to deliver performance improvements on every level."

"Our internal team was matched with unprecedented international collaboration from our global partners and suppliers, who together broke new ground in terms of virtual collaboration due to the COVID-19 pandemic including around the clock efforts to bring expertise and field experience to bear in ways never thought possible. We achieved all this amid the COVID-19 pandemic, while always keeping our team member safety as our top priority. This combined team delivered exceptional performance throughout this record first year of production and is a true testament to their commitment to professional excellence," said Chris Bland, Vice President Manufacturing, Braskem America.

The construction and launch of production at the facility has positively affected the economy in the Texas Gulf Coast region, which employed approximately 1,300 development and construction workers. An additional 50 Braskem permanent, high-quality, full-time jobs were created to support long-term commercial production. The plant design was developed directly in-line with Braskem's commitment to sustainability and attention to eco-indicators such as emissions, water, and energy efficiency, as well as recycling and waste reduction.

To support the sustainable use of polypropylene through the development of, and investment in, the Circular Economy, Braskem America committed to being a founding member and funding partner of the Polypropylene Recycling Coalition, with a primary focus on increasing U.S. polypropylene recovery and reuse. To learn more about the Polypropylene Recycling Coalition, the founding members, and how to join, visit https://recyclingpartnership.org/polypropylene-coalition . For additional information about Braskem's circular economy position please visit online at www.braskem.com/circulareconomy .

Related News

Press Releases

More news

From Air to Plastics: Norsk e-Fuel and Braskem Partner to turn Captured Carbon into Long-Lasting Products

With Braskem's I'm greenTM bio-based Polyethylene, Balsam Hill Made the World's First Plant-Based Plastic Christmas Trees

Braskem Unveils Bio-based Product Innovations at K 2025

Braskem reinforces its leadership in sustainable solutions at K Fair 2025

Braskem Unveils Updated Life Cycle Assessments for I'm greenTM bio-based Portfolio, Reinforcing Commitment to Sustainability

Braskem Global

Braskem Global

Braskem Idesa

Braskem Idesa

Braskem USA

Braskem USA

Braskem Europe

Braskem Europe