New 3D Dimensions™ – powered by Braskem Design Competition

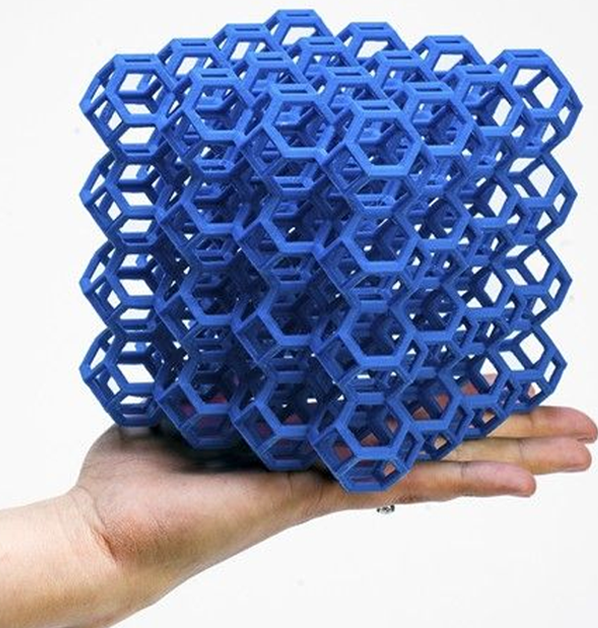

Braskem, one of the world’s largest polyolefins producers, is quickly becoming a market leader known for innovative materials serving the fast-growing 3D printing and additive manufacturing technology communities. Braskem’s leadership in polymer solutions is supported by its belief that there is a responsibility to create sustainable solutions through plastics and chemicals that can enhance people’s lives. Through Braskem’s portfolio of polypropylene (PP) 3D printing materials, industries can create customizable on-demand solutions that are lightweight, highly durable, and produce less material waste than traditional manufacturing processes.

New 3D Dimensions™ powered by Braskem design competition, in alignment with the company’s Global Sustainable Development Strategy , was developed to capture the imagination of student teams from across the United States and inspire them to develop the next generation of 3D printed designs that can benefit people and society. Whether it’s developing the next generation of electric vehicles, combating climate change, supporting people or animals with disabilities, or simply improving upon an existing design, we are looking for the next generation of 3D printing masters to lead forward with the very best 3D printing polypropylene can produce.

We are looking for design submissions

The theme for this year’s competition is Drone Frame Optimization.

Winners

Awards will be given out for first, second, and third place. The first place team will receive $10,000, second place team will receive $5,000 and third place team will receive $2,500. Teams will be limited to no more than 4 members per team

Timeline & submission deadlines

September 12

Registration

Opens

November 15

Submissions

Due

December 1

Finalists

Announced

March 31

Finalists

Submissions Due

April 17

Winners

Announced

Judging criteria

60% Quantitative Targeted Performance Assessment

Each Final Submission will be quantitively assessed based on how well the printed part achieved the targeted performance in relation to the performance of other competing teams using the table below. Each category will be assessed with a maximum award of 20%. When considering the 3 targeted performance categories, this will account for up to 60% of the team’s total potential score.

|

Team Ranking |

Percentage Awarded |

|

1 |

20 |

|

2 |

16 |

|

3 |

12 |

|

4 |

8 |

|

5 |

4 |

|

6 |

0 |

- Drone weight (20%)

- Maximum drone arm carrying capacity (20%)

- Total print time for all drone frame components (20%)

20% Design Creativity

- Uniqueness of design

- Design aesthetics

- Storage and integration of the electronics, wiring, and motors

- Design safety features

- Landing functionality

- Utilizing multiple materials

10% Sustainability/Design Optimization

- Part consolidation and integration to minimize joints and assembly

- Part orientation and geometry to minimize support material

- Sustainable material content

10% Fit and Finish of the final printed part

- Final part resolution

- Type of post-processing (if any) was required to achieve final surface finish (i.e sanding, grinding, CNC, sandblasting, etc.)

- Textures and finish

Meet the judges

Dylan George

Application Engineering Manager, Ultimaker

Natalie Herrin

Systems Engineer at Essentium Inc.

Adam Hecht

Co-founder, DiveDesign

Michelle Sing

Technology Development Engineer, Braskem

Aneesh Joshi

Applications Development Engineer, Braskem

Submitting

your design

Judging of the design competition will be done in two rounds. In the first-round, teams will need to submit their design proposals for initial review. Design proposals will be evaluated based on the questions provided below. Please be as descriptive as possible with your ideas.

If your design proposal is selected for the second round of the competition, your team will be asked to refine your idea and create a working .stl file as well a final working prototype that has been 3D printed. Each team will have four (4) spools of Braskem polypropylene filament (PP) to be used for prototyping the final printed part. Additional material may be available upon request.

Program rules

Be sure to review the program’s rules prior to registering:

Click hereTo learn more about Braskem’s 3D Printing portfolio innovation please visit: https://www.braskem.com/usa/3d-printing

Let’s get printing!

We are hiring!

If you’re interested in applying for a career or internship with Braskem,

please visit

www.braskem.com/usa/career

.