Braskem launches new Maxio resin capable of increasing big bag production

The raw material was specially developed to meet the high level of requirement of the clients in relation to mechanical properties of the raffia tape and guarantee benefits of increased productivity at the extrusion stage.

In the search for solutions that increase productivity and reduce the costs of clients who produce big bags (used for packing and transporting grains, fertilizers, ores, and chemicals), Braskem has developed the new DP213A polypropylene resin, the new grade of the Maxio line . With its application, companies in the segment have increased their production by 30% without increasing their energy consumption.

DP213A is a resin with a low melt flow index containing anti-UV additive. The raw material was specially developed to meet the high level of requirement of the clients in relation to mechanical properties of the raffia tape and guarantee benefits of increased productivity at the extrusion stage.

"Most of Braskem's innovations are based on our interest in meeting the demands of clients, and the development of this new Maxio line is a good example of this. We have identified a fierce competition in the raffia sector, which has led companies to compete on the basis of prices. By applying the resin that we are now launching, they will be able to reduce their operating costs and the prices of their big bags, increasing their production capacity and consuming less energy," said Carolina Bulhões, Leader of the Application Engineering area at Braskem.

The development of products that make up the Maxio line is something that is in line with Braskem's commitment to promoting sustainability in the plastics chain. In November 2018, the company defined a series of global initiatives to boost the Circular Economy , including partnering with customers in the design of new products to expand and facilitate the recycling and reuse of plastic packaging, particularly those for single use. "Braskem's Positioning in the Circular Economy" can be accessed here .

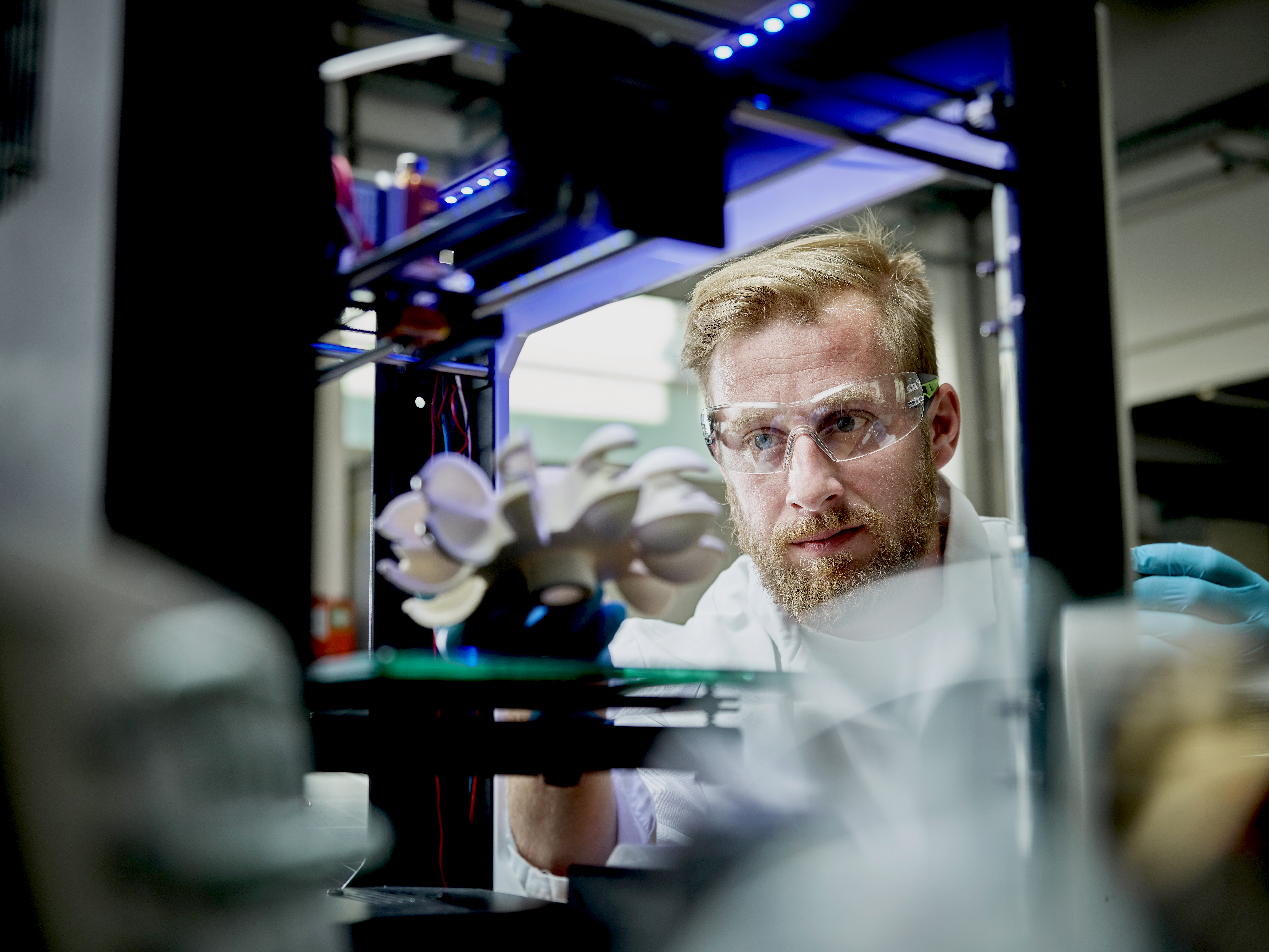

Success story: Propex achieves increased productivity and reduced energy consumption

Propex

, a textile company pioneering in the manufacture of laminated fabrics and a highlight in the production of big bags, has reported an increase of approximately 20% in its production capacity. According to the company's engineer, Patrick Camargo, the goal was to reach greater speed in the extrusion machines without causing the engines to reach their operational limits, and the resin DP213A presented by Braskem was the best solution for that.

"Braskem's ongoing pursuit of solutions that improve customer efficiency has provided us with great results. We have increased our production without consuming more energy, preserving our machines and maintaining the quality of our products," claimed the executive.

About Propex

For 40 years, Propex do Brasil has stood out in the segment as a modern company, pioneering in the development of innovative solutions. Growth and leadership in the market have been only possible thanks to our employees and to the investments made. With that, Propex has become over the years a leader in quality standards and the high performance of its products.

For more information related to press, please contact:

Fato Relevante

imprensa.braskem@agenciafr.com.br

Related News

Se você é um profissional da imprensa, a Braskem tem um canal feito só pra você.

Acesse aquiPress Releases

More news

Shell Chemicals and Braskem bring certified bio-attributed and bio-circular propylene and polypropylene to the U.S. market

Braskem announces partnership with Northwestern University for the development of CO2 conversion technology

Braskem invests in expanding capacity and partnerships for producing plastics from renewable sources

Braskem and Sojitz Corporation launch Sustainea

Braskem launches Wenew, its new global Circular Economy ecosystem

Braskem recognized by MIT as one of Brazil's most innovative companies

Customers

Become a Braskem customer

Braskem is one of the largest suppliers of chemical and petrochemical products in the world, recognized for its focus on sustainable development, innovation and quality.

We believe in lasting partnerships, we have a broad portfolio of products and we work together with our customers to create new practical and sustainable solutions in all markets.

Talk to our sales team

Braskem Global

Braskem Global

Braskem Idesa

Braskem Idesa

Braskem USA

Braskem USA

Braskem Europe

Braskem Europe